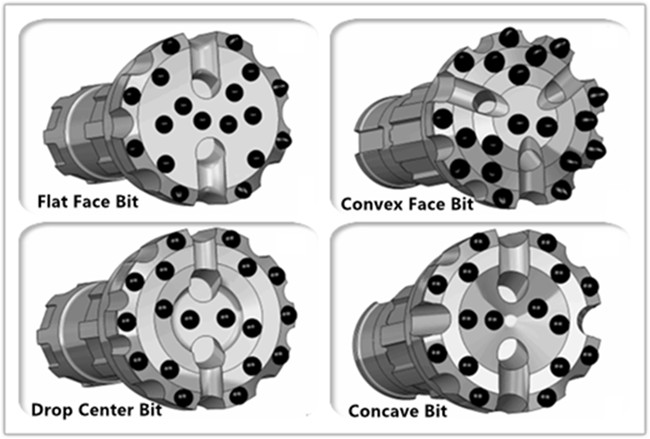

How to choose the right DTH bit for the project?

Flat Face Bit

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressure. Good penetration rates an resistance to steel wash.

Convex Face Bit

For high penetration rates in soft to medium-hard with low to medium air pressure. It is the most resistance to steel wash, and may reduce the load and wear on gauge buttons, but poor hole deviation control.

Drop Center Bit

For high penetration rates in soft to medium hard and fissured rock formations. Low to medium air pressure. Maximum hole deviation control.

Concave Bit

The all-around application bit face specifically for medium hard and homogeneous rock formations. Good hole deviation control and good flushing capacity.